To respond the needs at the production site, we advise consistently from basic design of various equipment to design and production. We manufacture equipment that meets the needs of our customers, such as molding equipment for semiconductors and equipment for assembling precision parts.

Molding equipment

We offer a lineup from R & D to mass production in accordance with product specifications and number of products.

We offer a wide variety of high-quality options, including our proprietary high-vacuum system and automatic coating system of release agent, which is developed and made by ourselves.

COMET (Standard Auto Mold Equipment)

- Improves unfilled and void by its own high-airtightness chamber structure

- Double-frame molds and back tape attachments

- Customizable for each product

- Large frames and boards substrate such as 100mm × 300mm

COMET-C (Auto Molding Equipment for Transparent Resin)

- "Lens shape" "MAP shape" "One side sealing" “Both side sealing” for LED and sensor

- Unique air tight chamber structure improves unfilled and void

- Equipped with automatic coating system of release agent

COMET-LS (Auto-mold Equipment for Liquid Silicone)

- Also can cope with resin containing phosphor and Nano filler

- Simple resin exchange system cope with small amount and large variety

- Equipped with automatic automatic coating system of release agent

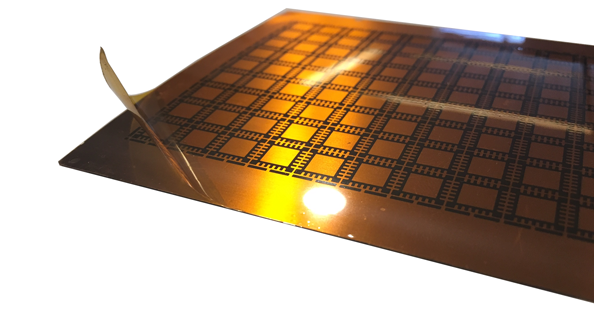

Automatic tape sticking and peeling device

Tapes are automatically attached and peeled off to surface mount type frames such as QFN.

Not only pasting prior to bonding, but also pasting after bonding.

It is effective against defects that the bonding is based on tape cushioning and thermal conductivity.

In addition, the stand-alone, it can also be incorporated inside the automatic molding machine.

Composition molding equipment

By in lining equipment that was divided into three units, the first mold, the first tie bar cut, and the second mold,

it is possible to improve production efficiency, promote automation, and further improve product yield.

Insert molding equipment

We are proposing and manufacturing a series of production equipment, such as “material supply → supply material inspection → molding → product inspection → NG cut → product storage”, which makes it possible to improve production efficiency.

We have many experiences such as connectors, camera modules, precision motors, relays and contacts.

Units can be organized according to customer requirements.

Auto Assembly Machine

We supply various parts from the parts feeder and perform assembly and press fit automatically.

There are many achievements in precision motors, connectors, contact parts, etc.